Unlike cast in-situ structures, precast structural members need to be checked for multiple design stages other than final stage.

[1] In precast structures since members are casted in factory & then transported to site for assembly, there are multiple stages involved for which the member needs to checked.

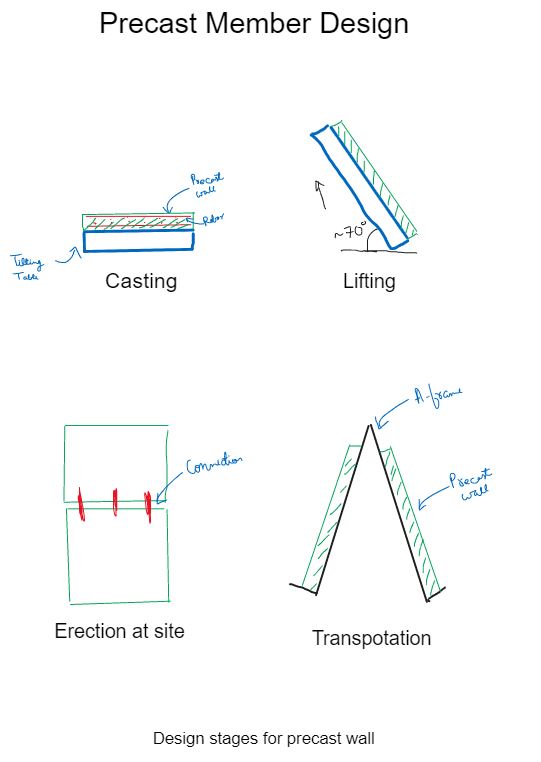

[2] These are the design stages for which precast elements are checked.

a) Release or demolding

b) Lifting at factory

c) Storage

d) Transportation

e) lifting at site

f) Erection or assembly

g) Final stage or in-use

[3] The check at these intermediate stages depends on the way the element is lifted at the factory & at the site, the support condition during lifting.

[4] Different precast elements have different casting & lifting methods.

Walls are mostly cast on the tilting table & lifted vertically using two or more points and then transported to site stacked on A-frames.

Solid slabs are cast on bed and lifting using four points in their plane.

Hollow core slabs are extruded and lifting using chain/belt lifting.

[5] Further it should be noted that precast elements are lifted & transported quite early, hence they do not attain their full strength during intermediate stages.

So the reduced concrete strength should be taken into account while checking for these stages.

This is a post for various design stages for precast member design.

Any comments or suggestions are welcomed.

Comments are closed