As a structural engineer you are often faced with a challenge to reduce the beam depths to have more clear height in the structure.

[1] increasing the concrete grade and reinforcement are few ways to curb the section the size, but these have very minimal reduction on the depth of the beam.

[2] Making the beam a prestressed member can be a good solution in this case.

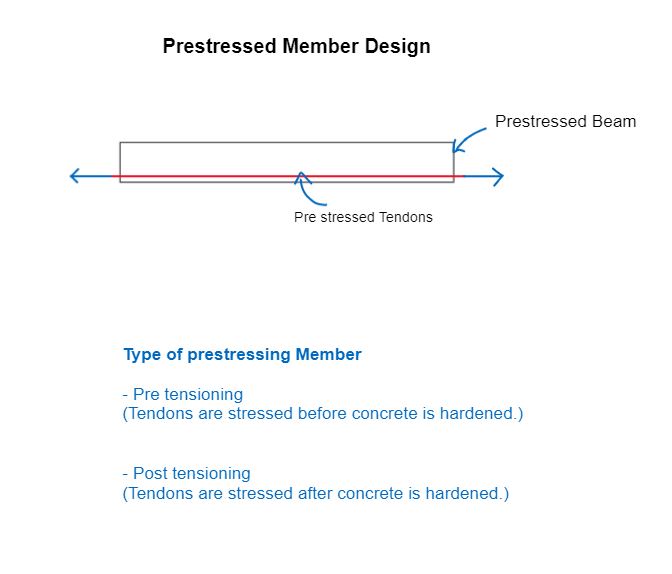

[3] A prestressed beam is the concrete beam which has strands/tendons that are stressed even prior to the application of loads.

The step to stress these tendons is called prestressing.

[4] The prestressing is done by means of jacking and tension is created in the tendons/strands.

[5] Prestressing can be by post tensioning or pre tensioning.

Pre-tensioing: The tendons are stressed prior to the concreting and then tendons are cut.

Post-tensioning: The tendons are stressed once the concrete is hardened.

[5] The provision of tendons help to span on longer length with less concrete section.

Additional checks for concrete crushing at ends, deflection at various design stages and prestressing loss should be done apart from flexure & shear checks.

[6] IS 1343 is the Indian code which stipulates the requirements for prestressed concrete.

Concise beam, Strusoft Prestess, ADAPT PT are few design programs which are used prestressed member design.

This is a post of prestressed member design, any comments or suggestions are welcomed.

Comments are closed